Case Studies

DESY offers industrial companies a wide range of opportunities to use its extensive research infrastructure.

Companies that need synchrotron radiation for their own research and development, for example to study materials or active substances at the atomic level or to optimise manufacturing processes, often need a large-scale research facility for this purpose that they do not have themselves. DESY offers these industrial users access to its X-ray radiation source PETRA III.

In recent years, companies from the pharmaceutical, chemical, automotive and electrical industries as well as from the aerospace industry have carried out measurements at PETRA III. Some sucess stories of how high-energy X-ray light provides clues to deciphering the smallest structures can be found here.

Measurements at PETRA III

Life Science, Pharma and Biotech Industry

Companies from life science, pharmaceutical and biotech industries are using the synchrotron light source PETRA III with its state-of-the-art beamlines to identify the structure of proteins at the molecular level and for the development of new drugs. Next to DESY’s own experimental stations, the European Molecular Biology Laboratory (EMBL) operates three beamlines at PETRA III and offers industrial services at its’ Hamburg location. Methods include crystallography, serial crystallography, small angle scattering, powder diffraction and different imaging technologies.

Companies from life science, pharmaceutical and biotech industries are using the synchrotron light source PETRA III with its state-of-the-art beamlines to identify the structure of proteins at the molecular level and for the development of new drugs. Next to DESY’s own experimental stations, the European Molecular Biology Laboratory (EMBL) operates three beamlines at PETRA III and offers industrial services at its’ Hamburg location. Methods include crystallography, serial crystallography, small angle scattering, powder diffraction and different imaging technologies.Discovering Structural Information in Degrader Molecules

Captor Therapeutics, a biopharmaceutical company that focuses on developing protein degradation drugs for cancer and autoimmune diseases, used the High-Throughput Macromolecular Crystallography Beamline at DESY to obtain precise crystallographic data for their structure-based drug design.

New ways to package and deliver RNA into human cells

BioNTech, together with the University of Mainz conducted an investigation at EMBL's beamline P12 at PETRA III to better package mRNA into nanoparticles for vaccines and individualised medicines.

Synchrotron radiation for the structural analysis of proteins

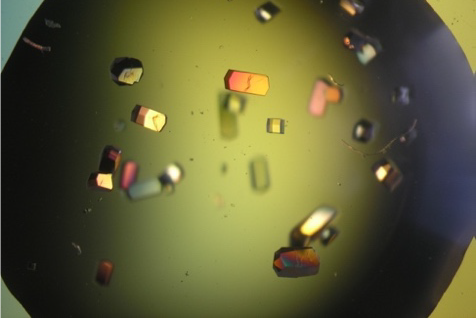

The biotech company CrystalsFirst has carried out protein crystallography on beamline P11 to investigate how 87 different fragments bind to a kinase.

Characterisation of higher-order structures of biosimilars

SARomics Biostructures AB validates the higher-order structures of biosimilars, i.e. copycat products of biopharmaceuticals. At PETRA III, a comparison of biosimilars was carried out using synchrotron-based small-angle X-ray scattering (SAXS).

Construction Industry

New materials and a deeper understanding of existing materials are paving the way to shape a sustainable future. There are a variety of analytical methods from which companies in the construction industry can benefit through measurements at the synchrotron. For example, powder diffraction and the pair distribution function method (PDF) were used to produce insights for the production of better cement from biomass ash.

New materials and a deeper understanding of existing materials are paving the way to shape a sustainable future. There are a variety of analytical methods from which companies in the construction industry can benefit through measurements at the synchrotron. For example, powder diffraction and the pair distribution function method (PDF) were used to produce insights for the production of better cement from biomass ash.Structure Properties of Heattreated Stone Wool Insulating Material

Rockwool and DTI have charcterized a stone wool insulation solution by using synchrotron X-ray powder diffraction and backscattered electron imaging methods to better contain and prevent building fires.

Conversion of biomass ash into environmentally friendly cement

Renotech OY from Finland converts biomass ash into environmentally friendly cement that can be used in construction and as fire protection material. To better understand the chemical process, a measurement was carried out on beamline P02.1 at PETRA III.

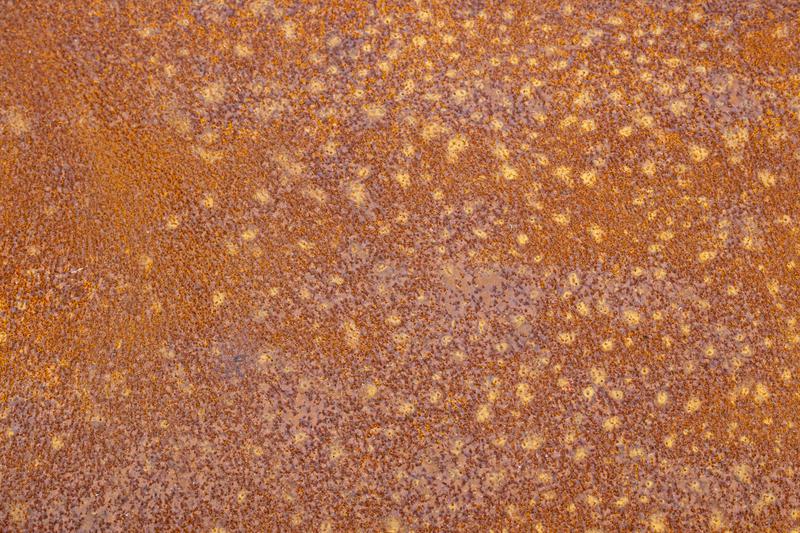

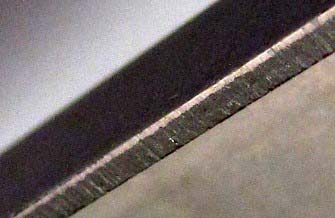

Hydrogen and strain interactions in duplex stainless steel

An attempt to understand the effect of hydrogen on the microstructural degradation of advanced stainless steels was made using the Swedish Material Science beamline P21.2 at the synchrotron PETRA III.

Phase transformations in metallic materials

Understanding phase transformations in metallic materials is important both for manufacturers of materials and for end users during welding or in operation. At PETRA III, an experiment was conducted in-situ to observe the kinematics of in duplex stainless steels.

Agriculture and Food Industry

Is it possible to increase the nutritional value of food? Through various investigations such as the pore structure in vegetables, the temperature influences on food or the identification of toxic trace elements in rice grains, analyses at the PETRA III synchrotron radiation source provide insights for industrial users from agriculture and the food industry.

Is it possible to increase the nutritional value of food? Through various investigations such as the pore structure in vegetables, the temperature influences on food or the identification of toxic trace elements in rice grains, analyses at the PETRA III synchrotron radiation source provide insights for industrial users from agriculture and the food industry.Greener Technologies for Sustainable Packaging

Yangi AB collaborated with the Danish Technological Institute (DTI) to develop an environmentally friendly dry-forming technology for cellulose-based sustainable packaging, using the PETRA III beamline P03.

Characterisation of thin extrusion-coated polymer films

Thin films made of polyethylene are a key component of Tetra Pak®'s packaging technology. To study the morphology of polyethylene (PE) films with high-brilliance synchrotron X-rays, Tetra Pak® has carried out measurements at PETRA III.

More stable packaging in variable environments

The Swedish pulp and paper manufacturer BillerudKörsnas is investigating the moisture-induced mechanical failure of paper. At PETRA III, synchrotron X-ray scattering experiments were carried out to observe the so-called mechano-sorptive creep (MSC) mechanism in situ.

Chemicall mill produces green fertilizer

X-ray experiments at PETRA III allowed scientists from the Ruđer Bošković Institute (IRB) in Zagreb, the Lehigh University in Bethlehem, the fertilizer company ICL, the University Zagreb and DESY to optimize a purely mechanical process for the production of Nitrogen and Calcium.

Automotive

Whether for more safety or greater efficiency through weight reduction: in the automotive industry, it is important to comprehensively investigate the materials needed to produce efficient vehicles. This is exactly what the PETRA III synchrotron radiation source at DESY helps with its highly brilliant X-rays. The methods range from powder diffraction to X-ray fluorescence microscopy. For example, the behavior of a material under mechanical load or battery components for the new era of electromobility can be investigated.

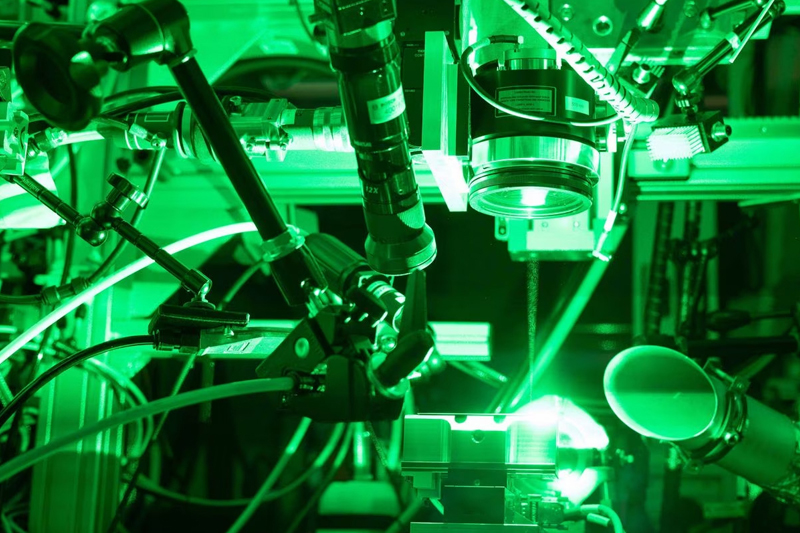

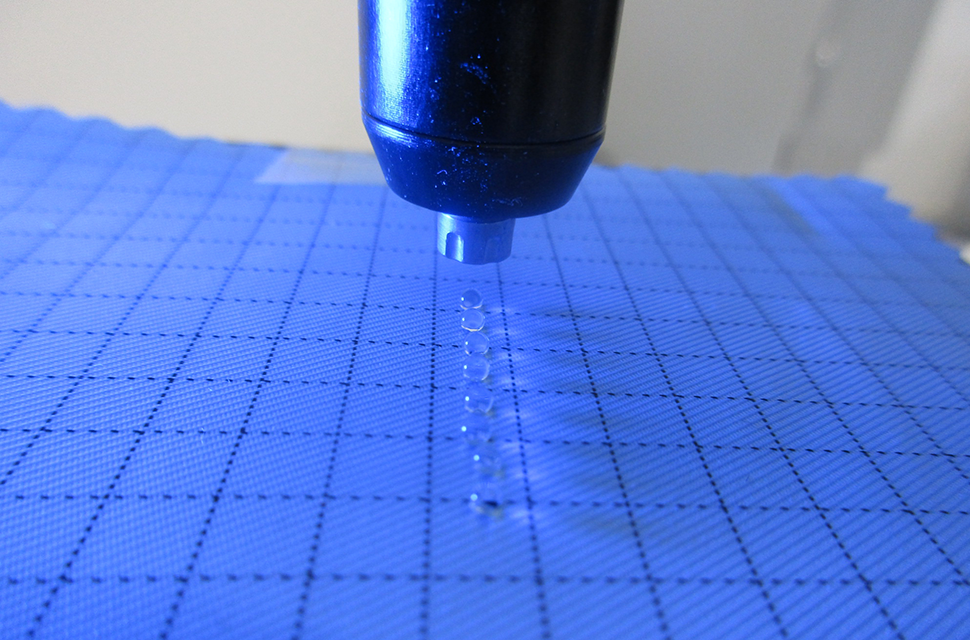

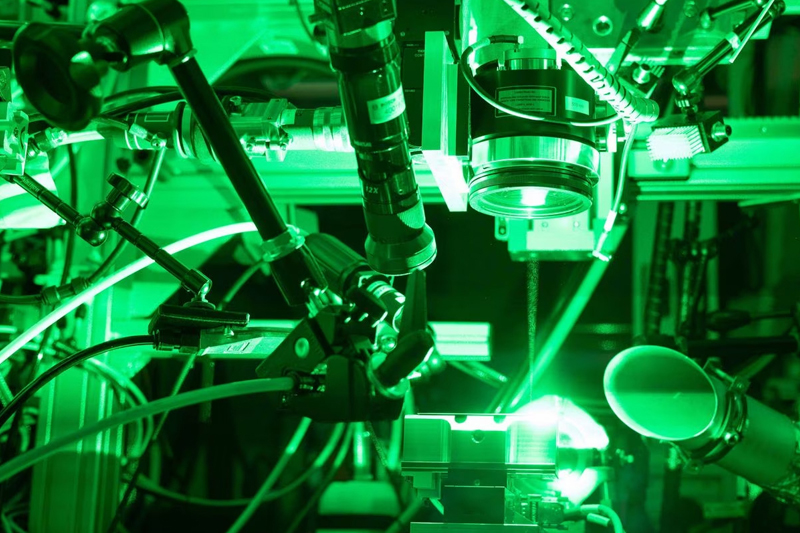

Whether for more safety or greater efficiency through weight reduction: in the automotive industry, it is important to comprehensively investigate the materials needed to produce efficient vehicles. This is exactly what the PETRA III synchrotron radiation source at DESY helps with its highly brilliant X-rays. The methods range from powder diffraction to X-ray fluorescence microscopy. For example, the behavior of a material under mechanical load or battery components for the new era of electromobility can be investigated.Welding high-performance electronics with green laser

A collaboration between TRUMPF, Fraunhofer ILT, DESY, and Hereon provided the most detailed insights into laser welding processes to date thanks to PETRA III,proving that green lasers are ideal for welding high-performance electronics.

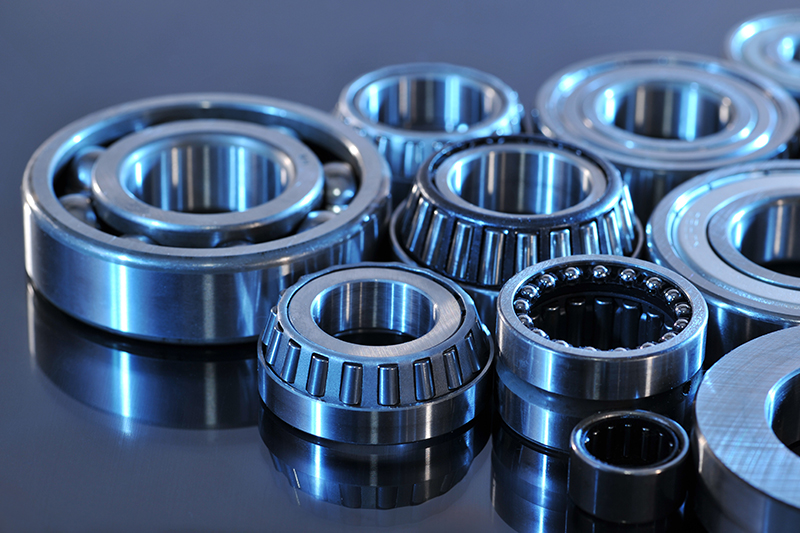

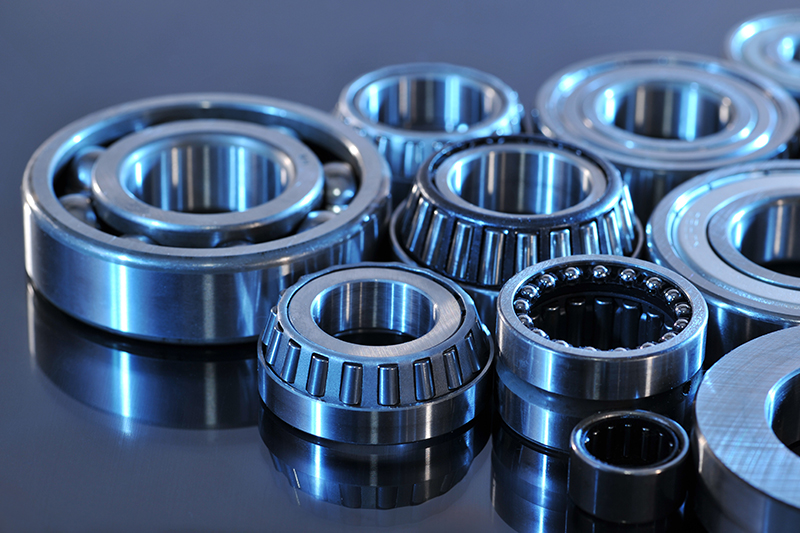

Eco-friendly bearings using novel steel

Scatterin AB and Ovako AB teamed up to investigate the microstructure of steel to manufacture more compact and lighter bearings, with PETRA III’s brilliant synchrotron light.

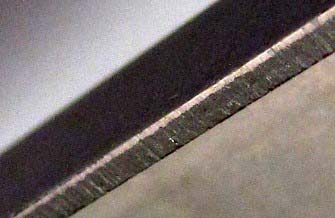

Microscopic stress states in ultra-high strength steel

Swedish steel company SSAB Europe and Swerim AB have performed high-resolution X-ray diffraction (XRD) measurements on the Swedish Materials Science Beamline P21 at PETRA III to investigate material failure and induced fractures of stainless steel.

Phase transformations in metallic materials

Understanding phase transformations in metallic materials is important both for manufacturers of materials and for end users during welding or in operation. At PETRA III, an experiment was conducted in-situ to observe the kinematics of in duplex stainless steels.

Shining light on nitrogen heteroatoms in carbon fibers

Structural batteries could offer a solution to the weight problem facing lithium-ion batteries (LIB) by using carbon fibers as structural components and as the cathode material. A combination of atom probe tomography and hard X-ray photoelectron spectroscopy looked into the distribution and chemical state of nitrogen atoms

Aerospace

In the field of aerospace technology and aircraft construction, insights for better and safer products are crucial. Lighter materials, greater fuel efficiency or better durability of surface coatings: Synchrotron-based analytical methods such as X-ray absorption spectroscopy, X-ray fluorescence microscopy or X-ray diffraction can provide new insights while also allowing materials to be examined under stress for the detection of potential structural damages at an early stage.

In the field of aerospace technology and aircraft construction, insights for better and safer products are crucial. Lighter materials, greater fuel efficiency or better durability of surface coatings: Synchrotron-based analytical methods such as X-ray absorption spectroscopy, X-ray fluorescence microscopy or X-ray diffraction can provide new insights while also allowing materials to be examined under stress for the detection of potential structural damages at an early stage.Understanding Strain-age Cracking in Superalloys

Malmö University and GKN Aerospace conducted in-situ diffraction and tomography studies on nickel-based superalloys. The insights will be used to develop next generation jet engine materials.

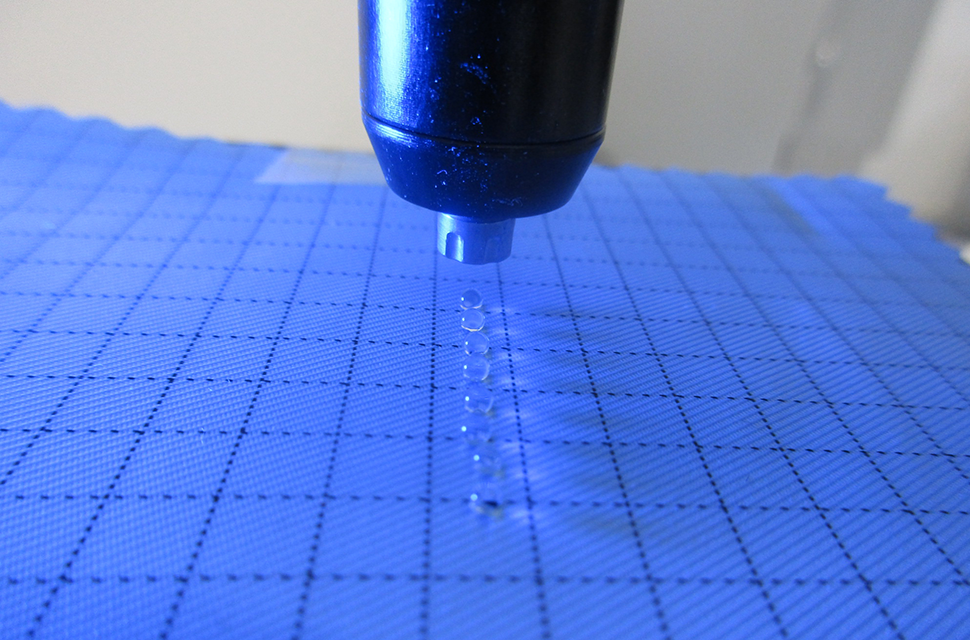

Cleanroom clothing against infectious droplets

OHB System AG has examined the protective effect of cleanroom clothing from satellite production for potential use in the medical sector. This happened due to the global shortage of suitable protective clothing for medical, nursing and care staff at the beginning of the Corona pandemic.

Energy Sector

Investigating and understanding new materials and systems for solar cells, fuel cells or batteries are possible with the synchrotron radiation source PETRA III. The brightness and high brilliance of the X-rays offer far better opportunities than other types of X-ray radiation sources and allow insights into the physical properties of the materials used in the energy industry.

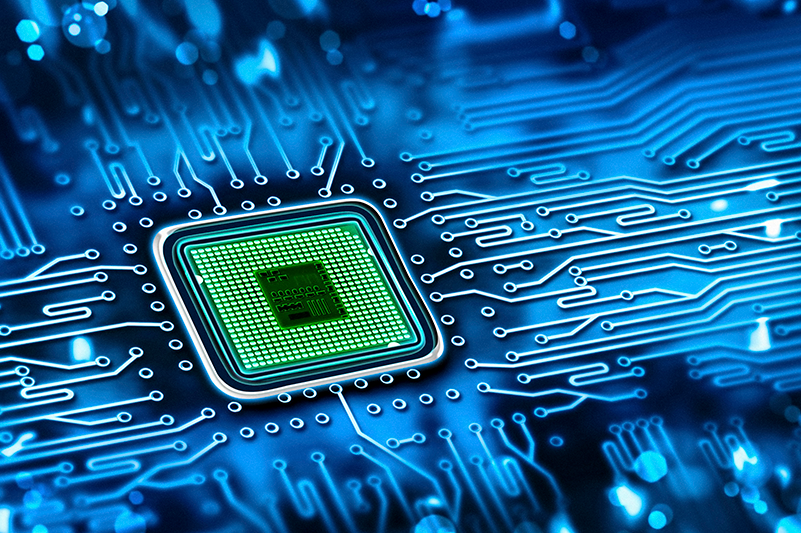

Investigating and understanding new materials and systems for solar cells, fuel cells or batteries are possible with the synchrotron radiation source PETRA III. The brightness and high brilliance of the X-rays offer far better opportunities than other types of X-ray radiation sources and allow insights into the physical properties of the materials used in the energy industry.Nondestructive ptychography for defect localization in microelectronics

High-resolution images of a microchip were generated using the ptychographic nanoanalytical microscope PtyNAMi on beamline P06. The synchrotron radiation from PETRA III makes defect characterization in microelectronics particularly reliable, as microchips can be examined non-destructively with coherent X-rays.

Examining water-splitting photocathode materials

SajTOM Light Future observed differences in the local structure and oxidation state of semiconductor materials, to be used as highly efficient photocathodes for producing green hydrogen.

Insight into the inner life of simple AAA batteries

Lithium-based batteries can be built lighter and smaller than other types due to their high specific energy density. To better understand mechanisms in batteries such as degradation, capacity loss or charging speed, a non-invasive 3D imaging technique was carried out at PETRA III that enables the identification of the chemical composition on a micrometre scale.

Shining light on nitrogen heteroatoms in carbon fibers

Structural batteries could offer a solution to the weight problem facing lithium-ion batteries (LIB) by using carbon fibers as structural components and as the cathode material. A combination of atom probe tomography and hard X-ray photoelectron spectroscopy looked into the distribution and chemical state of nitrogen atoms

Material Science

Material science tries to answer the question how processing history of a material influences its physical properties. Analytical methods at the PETRA III synchrotron radiation source give unique insights into the structure of materials and provide clues to improve product performance, productivity and quality. Techniques useful for industrial research include (tomographic) imaging, small- and wide-angle X-ray scattering and various spectroscopy techniques. The Helmholtz Centre Hereon and the Royal Institute of Technology Stockholm both operate beamlines at PETRA III, which can be used for industrial beamtime.

Material science tries to answer the question how processing history of a material influences its physical properties. Analytical methods at the PETRA III synchrotron radiation source give unique insights into the structure of materials and provide clues to improve product performance, productivity and quality. Techniques useful for industrial research include (tomographic) imaging, small- and wide-angle X-ray scattering and various spectroscopy techniques. The Helmholtz Centre Hereon and the Royal Institute of Technology Stockholm both operate beamlines at PETRA III, which can be used for industrial beamtime.Non-destructive residual stress profiling in large bearing components

The Swedish company SKF (Svenska Kullagerfabriken) has carried out non-destructive measurements of residual stresses in large bearings on PETRA III. This allows the heat treatment process in the production of large bearings to be optimized and the quality and lifeperiod of the bearings to be improved.

Structure Properties of Heattreated Stone Wool Insulating Material

Rockwool and DTI have charcterized a stone wool insulation solution by using synchrotron X-ray powder diffraction and backscattered electron imaging methods to better contain and prevent building fires.

Waste Streams for Sustainable Materials

CelluComp came together with DTI at PETRA III to investigate a new cellulose-based material derived from the extraction of nanocellulose fibers from sugar beet in order to understand the mechanical properties of the renewable material.

Greener Technologies for Sustainable Packaging

Yangi AB collaborated with the Danish Technological Institute (DTI) to develop an environmentally friendly dry-forming technology for cellulose-based sustainable packaging, using the PETRA III beamline P03.

Welding high-performance electronics with green laser

A collaboration between TRUMPF, Fraunhofer ILT, DESY, and Hereon provided the most detailed insights into laser welding processes to date thanks to PETRA III,proving that green lasers are ideal for welding high-performance electronics.

Eco-friendly bearings using novel steel

Scatterin AB and Ovako AB teamed up to investigate the microstructure of steel to manufacture more compact and lighter bearings, with PETRA III’s brilliant synchrotron light.

More stable packaging in variable environments

The Swedish pulp and paper manufacturer BillerudKörsnas is investigating the moisture-induced mechanical failure of paper. At PETRA III, synchrotron X-ray scattering experiments were carried out to observe the so-called mechano-sorptive creep (MSC) mechanism in situ.

Characterisation of thin extrusion-coated polymer films

Thin films made of polyethylene are a key component of Tetra Pak®'s packaging technology. To study the morphology of polyethylene (PE) films with high-brilliance synchrotron X-rays, Tetra Pak® has carried out measurements at PETRA III.

Conversion of biomass ash into environmentally friendly cement

Renotech OY from Finland converts biomass ash into environmentally friendly cement that can be used in construction and as fire protection material. To better understand the chemical process, a measurement was carried out on beamline P02.1 at PETRA III.

Microscopic stress states in ultra-high strength steel

Swedish steel company SSAB Europe and Swerim AB have performed high-resolution X-ray diffraction (XRD) measurements on the Swedish Materials Science Beamline P21 at PETRA III to investigate material failure and induced fractures of stainless steel.

Hydrogen and strain interactions in duplex stainless steel

An attempt to understand the effect of hydrogen on the microstructural degradation of advanced stainless steels was made using the Swedish Material Science beamline P21.2 at the synchrotron PETRA III.

Phase transformations in metallic materials

Understanding phase transformations in metallic materials is important both for manufacturers of materials and for end users during welding or in operation. At PETRA III, an experiment was conducted in-situ to observe the kinematics of in duplex stainless steels.

Cleanroom clothing against infectious droplets

OHB System AG has conducted a study to investigate the protective effect of cleanroom clothing, which is intended to protect against potentially infectious droplets in satellite production. At the PETRA III synchrotron light source, the Helmholtz Centre hereon provided support with high-resolution data in 3D.

Chemicals and Plastics

The chemical industry is looking particularly at making reactions more efficient and reducing potentially harmful substances. Catalysis in particular is an important subject of research. However, heterogeneous and sensitive samples complicate experiments and leave many questions about fundamental chemical and physical mechanisms unanswered. PETRA III offers the possibility to use experimental set-ups in operando via methods of X-ray diffraction and X-ray spectroscopy. In recent studies scientists combined y-ray tomography methods with x-ray fluorescence measurements on catalyst particles to gain unique insights.

The chemical industry is looking particularly at making reactions more efficient and reducing potentially harmful substances. Catalysis in particular is an important subject of research. However, heterogeneous and sensitive samples complicate experiments and leave many questions about fundamental chemical and physical mechanisms unanswered. PETRA III offers the possibility to use experimental set-ups in operando via methods of X-ray diffraction and X-ray spectroscopy. In recent studies scientists combined y-ray tomography methods with x-ray fluorescence measurements on catalyst particles to gain unique insights.Examining Catalysts

Haldor Topsøe, a multinational chemical company specializing in the development and production of catalysts for the chemical, fertilizer and petroleum industries; studied the structure of catalysts and the interaction between their components to develop improved industrial products.

Examining water-splitting photocathode materials

SajTOM Light Future observed differences in the local structure and oxidation state of semiconductor materials, to be used as highly efficient photocathodes for producing green hydrogen.

Waste Classification via the Speciation of Zinc and Copper Compounds

The concentration of zinc in incineration residues is a major contaminant. Using X-Ray absorption spectroscopy (XAS) at PETRA III has helped the Water Research Centre (WRC) in the process to accurately characterize waste.

Solving the crystal structure of novel complex materials with X-ray diffraction

The Polish chemical company FAMAR in Dankowice produces chemical catalysts for industrial processes. To understand the crystal structure of these novel materials, high-resolution X-ray diffraction (XRD) was performed at Beamline P02 at DESY.

Characterisation of thin extrusion-coated polymer films

Thin films made of polyethylene are a key component of Tetra Pak®'s packaging technology. To study the morphology of polyethylene (PE) films with high-brilliance synchrotron X-rays, Tetra Pak® has carried out measurements at PETRA III.

Chemicall mill produces green fertilizer

X-ray experiments at PETRA III allowed scientists from the Ruđer Bošković Institute (IRB) in Zagreb, the Lehigh University in Bethlehem, the fertilizer company ICL, the University Zagreb and DESY to optimize a purely mechanical process for the production of Nitrogen and Calcium.

Services

How can my company gain access to DESY's PETRA III X-ray radiation source? How can industrial user secure beamtime flexibly and directly? The Innovation and Technology Transfer (ITT) department will help you and develop customised, individual services depending on the problem.

More Cases

You can find more cases from and with DESY on the Maxess Industry Arena website. The platform of the Swedish synchrotron MAX IV combines success stories of the industrial use of European large-scale research facilities in a central ecosystem.

More information

Your contact for PETRA III

Are you interested in beamtime at PETRA III? Please contact Oliver Wendt, Manager Innovation Services in the Business Development Office.