SPLASHH: Further development of compact accelerators using 3D printing

As part of the "SPLASHH" project, DESY, Fraunhofer IAPT and TUHH have used additive manufacturing technologies for the further development of plasma cells in compact accelerators, thereby providing important impetus for the industrialization of 3D printing.

Under the title "SPLASHH - Shaping Plasma Accelerators in the Hanseatic City of Hamburg", DESY, Fraunhofer Institute for Additive Production Technologies IAPT, and Hamburg University of Technology (TUHH) joined forces in June 2022 to drive forward the development of compact laser plasma accelerators using 3D printing. 3D printing as an additive production technology that is ready for series production offers the potential to produce complex shapes and components with minimal use of materials. The project, funded by the Ministry of Science, Research, Equality and Districts (BWFGB), has now come to a successful conclusion.

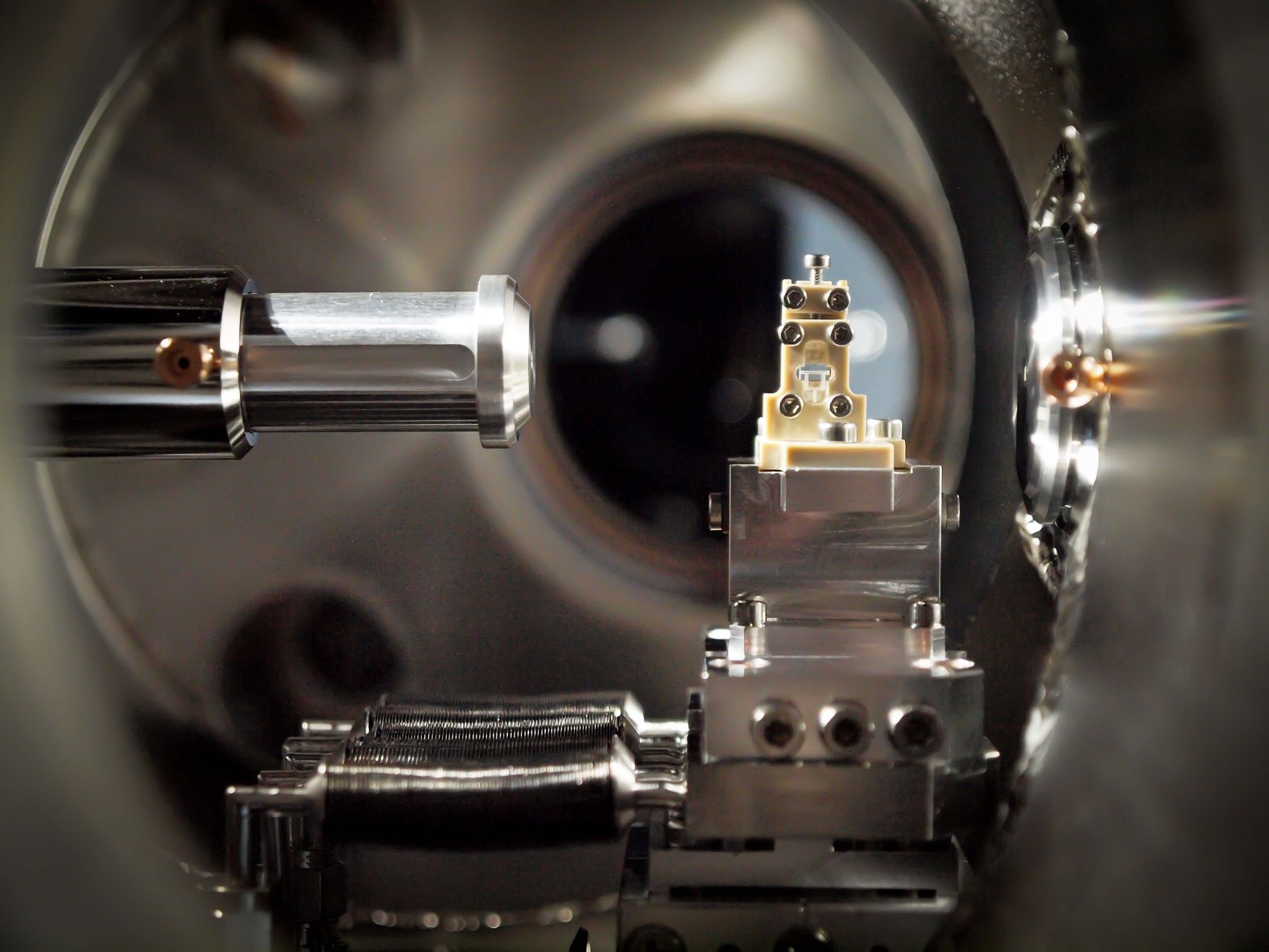

The project developed innovative plasma cell design options for use in compact accelerators. The presentation shows key elements of the plasma source, including a glass chip produced by selective laser etching, in which the plasma acceleration takes place, as well as a 3D-printed chip holder made of copper.

Fraunhofer IAPT was able to successfully produce the copper holder and optimize the process parameters to ensure production is in line with requirements. This included the successful processing of high-purity copper using Laser Powder Bed Fusion (LPBF), even for very complex requirements. Copper was chosen as the material due to its excellent thermal conductivity.

The method of selective laser-induced etching (SLE) at TUHH made it possible to etch the finest 3D structures into a quartz glass chip. This resulted in complex channel structures with particularly high precision and scalability, which were previously unattainable. For the acceleration process, the channel structures are filled with a hydrogen-nitrogen mixture, which is ionized into a plasma through interaction with the intense laser driver pulse. Progress has also been made in the processing of sapphire glass, a material that is normally difficult to etch due to its chemical and physical properties.

The components were successfully installed and tested in the LUX laser-plasma accelerator at DESY. For quality assurance purposes, tomography methods were also established and further developed on beamline P21.2 in collaboration with Fraunhofer IAPT. The high-resolution synchrotron analysis made it possible to precisely understand and evaluate both the 3D printing process and the 3D components.

This project lays the foundation for increased networking between scientific institutions and industry in the Hamburg metropolitan region, with the aim of advancing the industrialization of 3D printing technology. The development of new process technologies is becoming increasingly important in light of the demanding requirements that the next generation of high-tech machines will place on parts and components.

published

- 2024/02/21

Press Contact

- innovation@desy.de